Self loader concrete mixer is a revolutionary machine that combines concrete batching, mixing, and transportation into one compact and mobile unit. It allows contractors to produce fresh concrete directly at the job site – no need for extra equipment or external supply. With its automatic loading system, powerful engine, and high-precision weighing sensors, it ensures consistent quality and unmatched efficiency for all types of construction work.

Whether used in rurual infrastructure, urban development, or small-scale residential projects, this mixer significantly reduces manpower, fuel consumption, and overall production costs. Designed to handle tough site conditions, it offers exceptionsl mobility and reliability even in remote locations. For global contractors looking to boost productivity and profitability, the self loader concrete mixer is the perfect all-in-one solution.

| Models | LT-1.2/LT-2.0/LT-3.5/LT-4.0/LT-5.5/LT-6.5 |

| Capacity | 1.2m³ ~ 6.5 m³ per batch |

| Engine Power | 58 ~110 kW |

| Mixing Time | 15-20 minutes per batch |

| Drum Rotate | 270°/290° |

| Applications | Roads | Rural Housing | Infrastructure Projects |

Why Choose A Self Loader Concrete Mixer

A self loader concrete mixer, also called a self loading concrete mixer, is an advanced type of mobile concrete mixing equipment. Unlike traditional mixers that require external loading and separate transport vehicles, a self loader mixer performs all tasks independently:

- It loads materials automatically using a hydraulic shovel.

- It mixes the concrete on-site with precise water and material ratios.

- It transports and discharges concrete directly to the work site.

This all-in-one design simplifies the construction process, minimizes human error, and improves productivity – making it especially valuable for projects in remote or underdeveloped areas.

Key Components And Working Principle

The self loader concrete mixer truck integrates several essential systems:

Hydraulic Loading System

The front bucket automatcally scoops aggregates and cement, ensuring precise loading.

Rotating Mixing Drum

Equipped with a 270°~300° swivel range for flexible discharge.

Cab with 360° Visibility

Allows operators to monitor mixing and unloading conveniently.

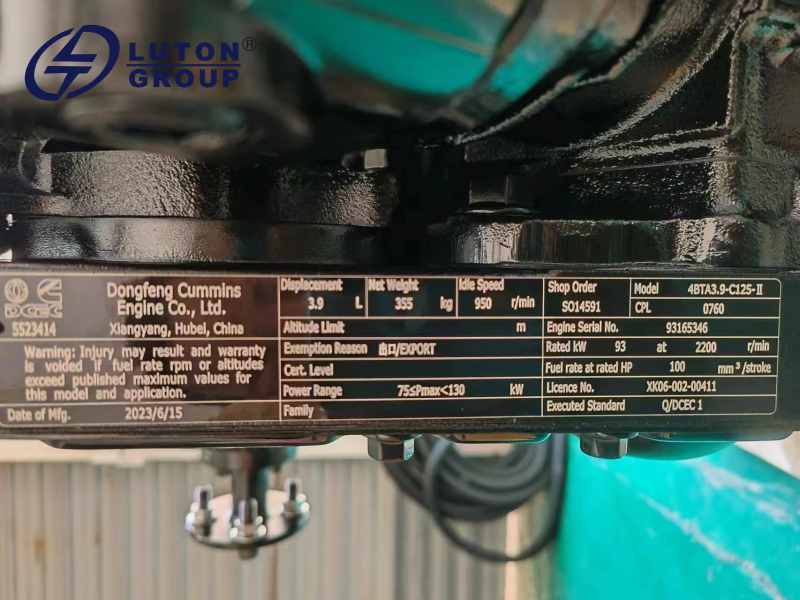

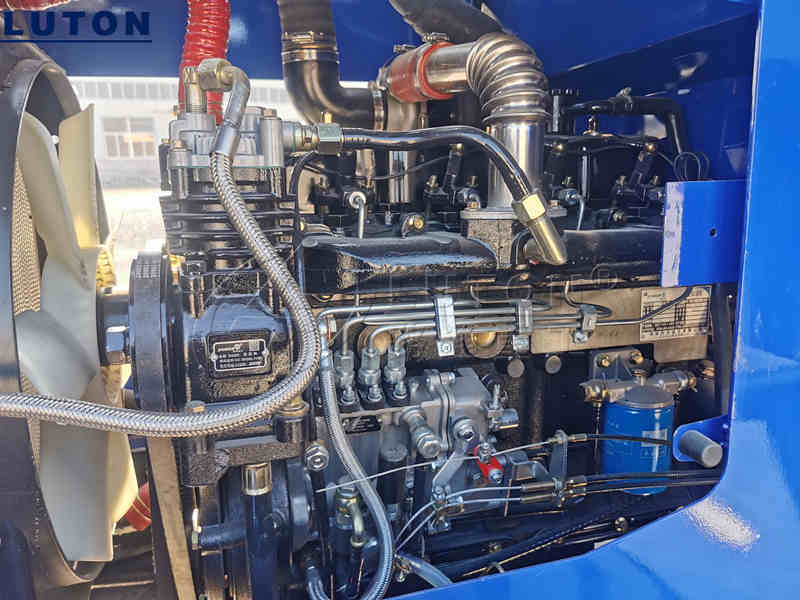

Powerful Engine and 4WD Chassis

Ensures strong performance on uneven terrain.

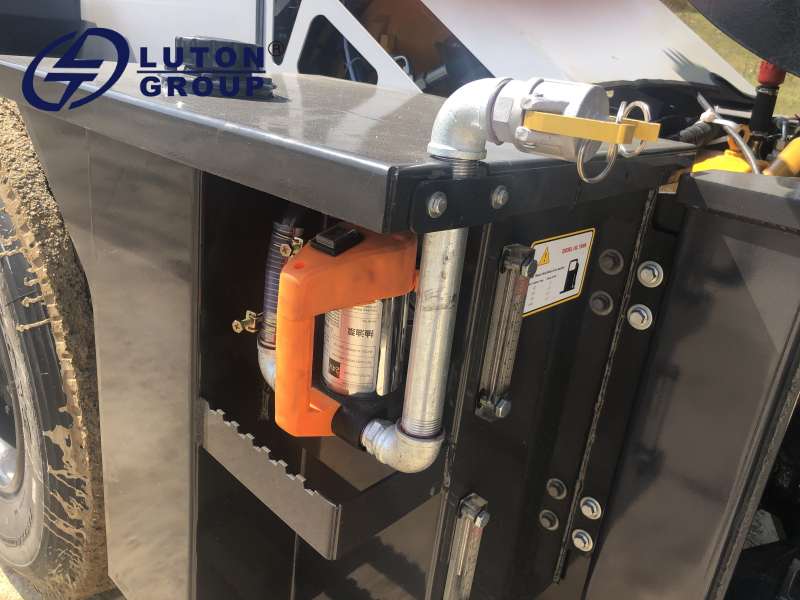

Water Supply System

Provides accurate water dosing for consistent mix ratios.

The working process is fully automated: materials are loaded into the drum, mixed evenly durig travel, and discharged directly into molds or structures.

Applications of Self Loader Concrete Mixers Worldwide

The self loader concrete mixer has gained popularity across the globe due to its versatility;

Rural Road Construction: Provides reliable mixing in areas without access to ready-mix supply.

Housing and Building Projects: Provides reliable mixing in areas without access to ready-mix supply.

Infrastructure Development: Used in bridges, tunnels, and irrigation systems.

Military and Emergency Works: Rapid setup and mobility make it suitable for urgent projects.

From India to Africa, Southeast Asia to South America, self loading mixers are transforming the way concrete is produced and delivered on-site.

LUTON Self Loader Concrete Mixer Models

LUTON offers a wide range of self loading mixer trucks designed for different project sizes.

| Model | Output Capacity | Mixing Drum | Engine Power | Features |

| LT-1.2 | 4.8 m³/h | 270° rotating drum | YUNNEI 58kW | Compact design, ideal for narrow sites |

| LT-2.0 | 8 m³/h | 270° rotating drum | Yuchai 78kW | Perfect for rural road projects |

| LT-3.5 | 14 m³/h | 270° rotating drum | Yuchai 85kW | Most popular global models |

| LT-4.0 | 16 m³/h | 270° rotating drum | Yuchai 91kW | Most popular global models |

| LT-5.5 | 22 m³/h | 270° rotating drum | Weichai 92-110kW | High output, large site efficiency |

| LT-6.5 | 26 m³/h | 290° rotating drum | Weichai 92-110kW | High output, large site efficiency |

All models are designed with a robust frame, efficient hydraulic system, and optional weighing sensors to ensure accurate concrete quality.

Why Choose LUTON Self Loader Concrete Mixers

LUTON GROUP has over 30 years of experience manufacturing and exporting construction machinery. By choosing our self loader concrete mixer, you benefit from:

- Factory-direct prices – no middlemen, ensuring cost efficiency

- Globle delivery – fast shipping to over 80 countries.

- Custom options – engine brands, drum capacities, and paint colors available.

- After-sales support – spare parts, online installation guidance, and maintenance training.

We’re committed to providing high-quality, reliable machines that increase productivity and reduce total project costs.

Export Cases Of LUTON Self Loader Concrete Mixers

Diesel Self Loading Mixer Truck To Eswatini

Self Loading Concrete Mixer Kenya For A Rural Road Project

Self Loading Mixer Truck In Central Africa

Self Loading Concrete Mixer For Sale In Ghana

Self Loading Concrete Mixer for Sale South Africa

LT1.2 Self Loading Concrete Mixer in Zimbabwe

LT5.5 Self Loading Concrete Mixer In Sudan

LT4.0 Self Loading Concrete Mixer Truck Sold In Cameroon

FAQ: Self Loader Concrete Mixer

Q1: What is the difference between a self loader and transit mixer?

A self loader mixes, loads, and transports concrete on-site, while a transit mixer only delivers pre-mixed concrete.

Q2: How many operators are needed to run a self-loader concrete mixer?

Typically, one trained operator can handle all functions, including loading, mixing, and discharging.

Q3: What types of concrete can it handle?

It is suitable for normal, dry, and semi-dry concrete used in roadwork, buildings, and precast projects.

Q4: How do I maintain the mixer?

Regular lubrication, cleaning the drum after use, checking hydraulic systems, and timely engine servicing ensure optimal performance.

Q5: What are the delivery and warranty terms?

We offer global delivery, with standard 12-24 months warranty depending on the model and region.

Q6: What is the lead time and shipping process?

Lead time typically ranges from 30-60 days. Shipping options include container, Ro-Ro, or bulk transport to over 80 countries.

Q7: Can the mixer be customized for different project needs?

Yes, we provide optional drum sizes, engine configurations, and accessories to suit specific site requirments.