In recent years, the application rate of self loading mixer truck is getting higher and higher. Whether in the city, in the town, or in the mountain areas, you can always see its small and exquisite posture. It can feed water and concrete materials, mix, unload and transport all by itself It helps countless customers to improve the work efficiency and accelerates the progress of the project. More and more people tend to buy one set of self loading mixer truck. Be patient! Learning more details on it will lead you to the reasonable choice.

Flexible & Convenient

Automatic & Intelligent

Cost-saving & Efficient

Durable & Stable

You can complete 5-12 batches per hours

Fuel Consumption 3-7L/H

Customized Services for Your Speciall Requirement

What Is A Self Loading Mixer Truck?

Self loading mixer truck, whose full name is self loading concrete mixer truck, which is a small and flexible intelligent concrete treating solution. Combined with multiple functions in one set, including self loading, self weighing, self mixing, self unloading and transporting, it can efficiently works on site, playing at least three roles, a loader, a mini concrete mixer plant and a truck. Hence, with a efficient working performance, self loading mixer truck can also save money, time and labors for investors.

Hot-sale Models of LUTON Self Loading Mixer Truck

| Equipment Model | LT-1.2 | LT-1.8 | LT-2.0 | LT-2.6 | LT-4.0 | LT-5.5 | LT-6.5 |

| Discharge Capacity (m3) | 1.2 | 1.8 | 2.0 | 2.6 | 4 | 5.5 | 6.5 |

| Output Capacity (m3/h) | 4.8 | 7.2 | 8 | 10.5 | 16 | 22 | 26 |

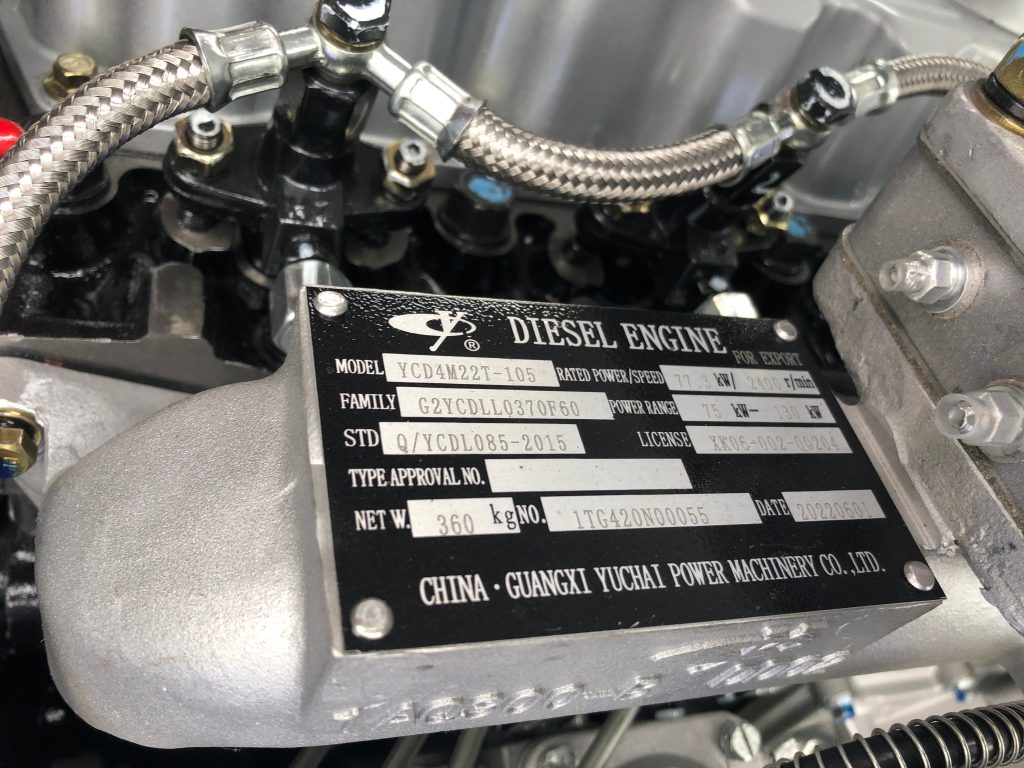

| Engine Model | YUNNEI | Yuchai 4102 | Yuchai 4102 | Yuchai 4102 | Yuchai 4108 | FAW XICHAI 6110 | Weichai Deutz 6105 |

| Rated Power | 58KW | 78KW | 78KW | 78KW | 91KW | 92KW~110KW | 92KW~110KW |

| Gear | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back |

| Oil Tank | 16 liters | 16 liters | 16 liters | 16 liters | 16 liters | 16 liters | 16 liters |

| Water Tank | 400L | 500L | 500L | 500L | 660L | 860L | 1465L |

| Water Supply | Time Relay | Time Relay | Time Relay | Time Relay | Time Relay | Time Relay | Time Relay |

| Overall Dimensions(L*W*H) | 6400*2550*2450 | 7300*2650*3750 | 7300*2650*3750 | 7800*2720*3000 | 7800*2720*3300 | 7500*2800*3600 | 8450*3100*4580 |

| Curb Weight (kg) | 4185 | 6500 | 6500 | 6500 | 8500 | 11200 | 12520 |

| Drum Rotate | 270º | 270º | 270º | 270º | 270º | 270º | 290º |

Price of LUTON Concrete Self Loading Mixer Truck

The price of Luton self loading mobile concrete mixers, also known as self loading concrete mixer, ranges from $10,000 to $70,000, related to the types and the produce capacity of the self loading truck mixers.

The price of pan type self loading concrete mixer is generally between $10,000 and $1,8000, while the price of drum type is about $15,000 to $75,000.

| Type | Model | Price |

| Mobile Diesel Self Loading Concrete MixerTruck with Drum Mixer | LT-1.2 | $15,000~$18,000 |

| LT-1.8 | $20,000~$29,000 | |

| LT-2.6 | $25,000~$32,000 | |

| LT-3.5 | $29,000~$35,000 | |

| LT-4.0 | $48,000~$58,000 | |

| LT-5.5 | $55,000~$60,000 | |

| LT-6.5 | $70,000~$75,000 | |

| Mobile Diesel Self Loading Concrete MixerTruck with Pan Mixer | LTP-1.2 | $10,000~$12,000 |

| LTP-1.6 | $14,000~$18,000 |

What Can Self Loading Mixer Truck Be Used For?

Self loading mixer truck with so many advantages and functions, can be used in various of construction projects.

Build Roads And Harden Roads

Self loading concrete mixer truck is the sharp weapon of building roads and hardening surface of roads.

The mixed concrete can be unloaded within the range of 270° around the truck, and the worker only need to flatten the concrete, simple and convenient. The design of small, flexible and reasonable body, four-wheel drive tires and other applications can make the mixer in the mountains, plateau, grassland, rural bumpy path “steady walk”.

Build House And Lay The Foundation

Concrete self loading mixer truck plays an important role in the construction of civil and commercial houses. It can provide required concrete materials for housing, foundation, factory plant projects and other constructions. And with small structure, it can also enter inside the factory workshop to finish the ground laying project.

Build The Floors

Square, playground and other public areas of the floor construction is also the specialty of concrete self-loading mixing truck project. The body in a large area of walking, mixing and unloading, the efficiency is very high.

Others

Self loading concrete mixer truck also plays its role in bridge, dam and viaduct constructions, as well as railway, subway and tunnel projects.

What Are The Advantages Of Self Loading Mixer Truck

Powerful turbo diesel drive, SUITABLE FOR walking and working on VARIOUS TERRAINS.

Diesel power drives the rotation of the mixing drum to fully ensure the uniform mixing of materials and produce HIGH QUALITY concrete products.

The hydraulic motor drives and controls the loading of the hopper, eliminating the need for extra labor and equipment intervention, SAVING COST of time, manpower and energy.

The mixing is HIGH EFFICIENCY. It only takes about 12 minutes to yield each batch of materials. Calculated according to the continuous working time of 10 hours per day, the daily output can reach 500 tons, which is several times the daily output of ordinary mixing equipment.

NO NEEDS OF any ELECTRIC POWER support, it can work stably in remote mountainous areas and other conditions without electricity, which common concrete mixing machinery is not competent to.

The saddle of the mixer truck chassis can drive the mixing drum to ROTATE HORIZONTALLY within a range of 270 DEGREES, and the discharge position is FLEXIBLE, which is suitable for various application sites.

INTELLIGENT WEIGHING and METERING SYSTEM that enables high quality output of concrete products.

SIMPLE and EASY CONTROLLING, allowing the operator to perform most of the workflow inside the cab through a series of control levers and switch buttons.

What Are The Main Components of LUTON Self Loading Mixer Truck

Diesel Engine System

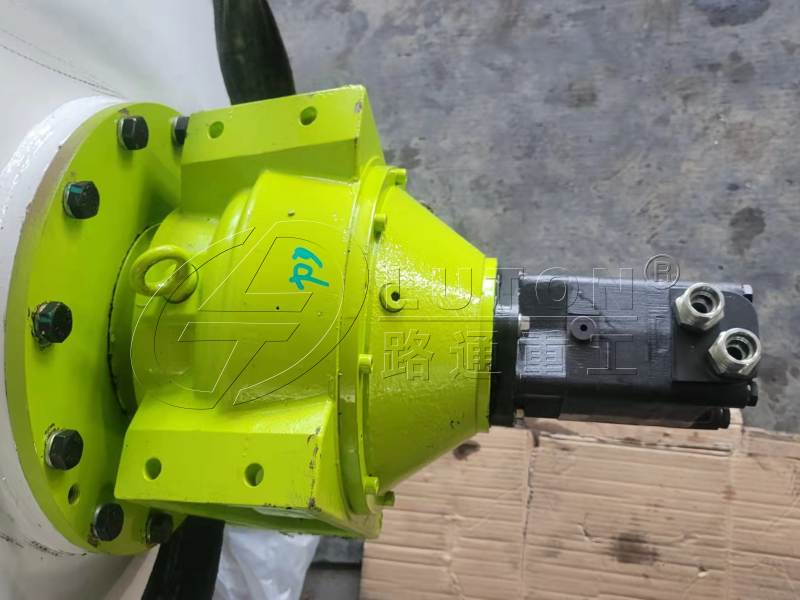

Hydraulic Driving Devices

Reducer

Mixing Drum or Mixing Pan

Loading Shovel

Water Tank

Driving Cab

Chassis

Steel Structure

How Does LUTON Self Loading Mixer Truck Work

When self loading mixer truck is used to produce concrete materials on site, only one operator and one auxiliary worker can efficiently complete the entire operation process, which is simple and convenient, saving time and manpower. Thanks to our engineers have designed such a highly integrated automatic mixing equipment and stable process control.

Its work process is completed in one go, and it is the result of the collaboration of multiple functional systems. Next, let’s take the drum type concrete mixer truck as an example to see how they work!

Loading Materials

The first step is certainly loading materials.

Without too many workers involved, the operator of the self loading mixer truck starts the diesel engine and the entire operating system in the operation cab, and then pulls the gear lever. Under the powerful drive of the hydraulic pump, the mechanical arms at the front of the truck drives the bucket loader to load cement,sand and other raw materials.

Measuring Materials

The raw materials are lifted by arms up to a certain height, the electronic weighing system switch is triggered and the mixer truck enter into the material weighing process, the second step of all working process.

Actually, there are two individual measuring system: aggregate weighing system and water measuring system. The two systems usually working separately and simultaneously.

To aggregate weighing, the self mixing concrete truck is equipped with a set of electrical weighing device and display instrument, which enable operators get the result directly and immediately. Accurate weighing results are the basis of good ingredient quality.

At the same time, water is measured by an electromagnetic flow meter and the water feed can be also read on the display screen in the operation cab.

Operators can easily activate the water pump by the driver’s seat to support water.

During measurement, the system sends an instruction, and the water supply pump starts.

At this time, the relay starts timing. When up to the preset value, the system sends an instruction to operator to stop the water supply pump, and the measurement ends.

When the loader reaches the highest point, the hydraulic control system obtains the signal of opening the discharge door at the bottom of the loader, and the weighed aggregate is unloaded into the mixer.

By this time, the third step begins.

Mixing Materials

Material mixing is the third step in the entire concrete production process, and it is also the core part. The weighed material is unloaded into the slowly rotating mixing drum by the loader, and at the same time, water is also added into the mixing drum. The mixing blades are designed and installed on the inner wall of the mixing drum to fully tumble and stir the Materials. Materials are constantly sinking with gravity until homogeneous concrete mix is

obtained. This process usually lasts about 2-5 minutes.

Unloading Concrete

Now it comes to the forth step, unloading process. In this stage, operator controls the mixing drum to rotate reversely through operating lever. In this way, the mixing blades will send the concrete mortar out of the drum.

With the help of the slewing support device on the chassis, the concrete mixing drum can be rotated horizontally by 270°. Sometimes, a removable chute is necessary, which is installed at the outlet of the mixing drum and extends the unloading distance.

And the chute can be rotated 90° mostly, which expands the paving area.

All of above mentioned realize the full area paving of concrete.

Cleaning Mixing Truck

At last, cleaning procession is also a working step that cannot be ignored.

The water tank is pressurized through the air reservoir of the braking system. And the pressurized water flows can be used to clean mixing tank system, loading port, unloading system, etc.

Keeping clean is the most basic daily maintenance for mixer trucks.

Gallery of LUTON Self loading Concrete Mixer Truck

Export Cases of LUTON Self loading Concrete Mixer Truck

LT3.5 Self Loading Concrete Mixer Exported to Vanuatu

LT1.2 Self Loading Concrete Mixer in Zimbabwe

LT1.8 Self Loading Concrete Mixer Truck to Serbia

LT4.0 Self Loading Concrete Mixer Truck Sold In Cameroon

LT3.5 Self Loading Concrete Mixer Sold to Indonesia