Cold weather conditions are often a major obstacle for construction projects. Freezing temperatures can slow down concrete setting times, create risks of cracking, and make it harder for workers and machines to perform at full capacity. For contractors operating in such environments, having the right equipment is critical. A self loading concrete mixer machine offers a practical solution by combining loading, mixing, transporting and discharging in one unit. More importantly, when designed for low-temperature operation, a self loading concrete mixer for cold climates ensures that projects continue smoothly even during the harshest winters.

| Model | Drum Capacity | Engine Power | Max Output | Drive Type |

| LT-1.2 | 1.2 m³ | 78kW | 5-6 m³/h | 4×4 |

| LT-2.6 | 2.6 m³ | 85kW | 10-12 m³/h | 4×4 |

| LT-3.5 | 3.5m³ | 92kW | 14-16 m³/h | 4×4 |

| LT-4.0 | 4.0m³ | 110kW | 18-20 m³/h | 4×4 |

| LT-6.5 | 6.5m³ | 110kW | 28-30 m³/h | 4×4 |

Challenges Of Concrete Mixing In Cold Climates

Construction in low temperatures presents several difficulties:

- Slow Setting Time – Concrete takes longer to cure in freezing conditions.

- Cracking Risk – Improper curing can lead to weak, cracked structures.

- Reduced Efficiency – Workers and machines operate less efficiently concrete, such as a pan mixer batching plant, often fall short in these conditions, making a more reliable solution necessary.

Why Choose A Self Loading Mixer For Cold Climates

A self loading concrete mixer truck is engineered to overcome the problems of cold weather construction. Here’s why it stands out:

- Automatic loading and precise mixing reduce delays.

- Insulated cabins and heating systems keep operators comfortable.

- On-demand concrete supply minimizes downtime in winter projects. By ensuring consistent concrete quality, the self loading cement mixer helps contractors maintain productivity and safety even in sub-zero conditions.

Key Features To Look For In A Cold-climate Self loading Mixer

To perform effectively in low temperatures, a mixer should include:

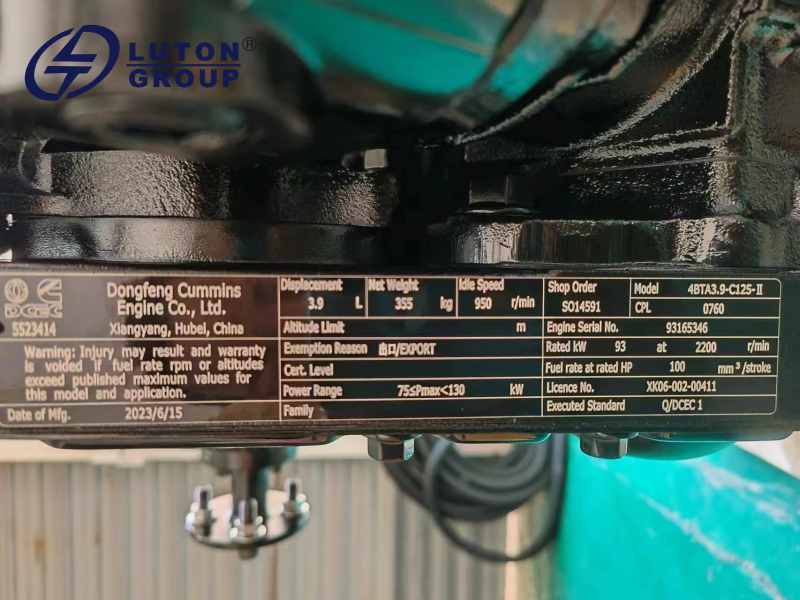

- Engine performance – Strong, fuel-efficient engines such as diesel power system of self loading concrete mixer, adapted for cold starts.

- Insulation and heating – Heated water tanks and insulated drums prevent freezing.

- Operator comfort – Enclosed cabins with heaters improve safety and reduce fatigue.

- Durability – Cold-resistant steel and anti-freeze systems enhance reliability. These features ensure that your self loading mobile concrete mixer or self propelled concrete mixer is ready for any winter construction challenge.

Applications of Self Loading Mixers In Cold Regions

Self loading mixers are widely used in cold areas such as Russia, Canada, and Northern Europe, where construction must continue year-round. Key applications include:

- Road building and repair in snowy regions using off road self loading concrete mixer.

- Infrastructure projects in remote or mountainous areas.

- Military and border construction in extreme climates. A self loading transit concrete mixer or self loading concrete mixer with pump ensures reliable performance in projects where traditional delivery may be impractical.

LUTON Self Loading Mixer In Cold Climates

At LUTON, we have successfully supplied China self loading concrete mixer models to clients operating in cold climates. For example, a customer in Eastern Europe reported:

- Improved efficiency by 30% compared to traditional mixers.

- Reduced manpower requirements by half with a small self loader concrete mixer.

- Enhanced durability and lower maintenance costs during winter. This proves that a LUTON self loading rough terrain concrete mixer is not only reliable but also highly cost-effective.

How To Maintain A Self Loading Mixer In Winter

To maximize lifespan and ensure reliable operation in freezing conditions:

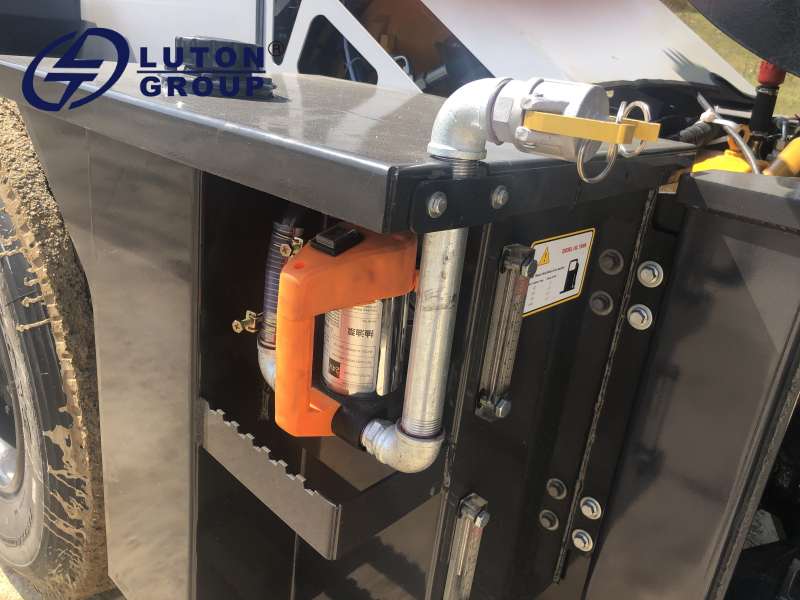

- Regularly check the engine and hydraulic system of the diesel self loading concrete mixer.

- Use anti-freeze coolant and low-temperature lubricants.

- Clean the mixing drum and water tanks after use to prevent freezing.

- Keep the cabin and controls dry and insulated. Proper winter maintenance for self loading mixers reduces downtime and avoids costly repairs.

Cost & ROI Of Self Loading Mixer For Cold Climates

While the self loading concrete mixer cost may range from $13,000 to $50,000, depending on capacity (such as 1.2m³ self loading concrete mixer or 6.5m³self loading concrete mixer for sale), it offers a significant return on investment:

- Reduces labor costs by combining multiple functions.

- Ensures reliable concrete supply in winter, avoiding project delays.

- Longer service life thanks to durable design. Choosing an affordable self loading concrete mixer ensures long-term savings and better profitability.

In conclusion, a self loading concrete mixer for cold climates is the ultimate solution for contractors working in freezing environments. With features like heating systems, durable design, and all-in-one functionality, it ensures consistent concrete production and cost savings.

At LUTON, we specialize in providing reliable self loading concrete mixer machines designed for all-weather performance. Contact us today to learn more about our models and request a quote to your project needs.

Export Cases Of LUTON GROUP

LT3.5 Self Loading Concrete Mixer Exported to Vanuatu

LT1.2 Self Loading Concrete Mixer in Zimbabwe

LT1.8 Self Loading Concrete Mixer Truck to Serbia

LT4.0 Self Loading Concrete Mixer Truck Sold In Cameroon

LT3.5 Self Loading Concrete Mixer Sold to Indonesia