In recent years, Honduras has experienced continuous growth in residential housing, small commercial buildings, and infrastructure construction. Many construction projects are distributed across different regions, often facing challenges such as:

- Limited access to ready-mix concrete plants

- High transportation costs for fresh concrete

- Unstable supply schedules and quality fluctuations

- Increasing labor costs and reliance on skilled workers

For this project, the customer in Honduras was mainly engaged in on-site concrete works, including foundations, slabs, and small structural elements. Their key requirement was not simply to “mix concrete”, but to achieve independent, flexible, and cost-controlled concrete production directly at the construction site.

Under these conditions, traditional solutions such as outsourcing ready-mix concrete or installing a small stationary batching plant were either too costly, inefficient, or inflexible. This created a strong demand for a mobile, integrated concrete production solution capable of adapting to varying job sites.

Project Type: On-site concrete production for residential & commercial construction

Machine Model: LT-3.5 Self Loading Concrete Mixer Truck

Location: Honduras

Investment Advantage: Reduced labor cost, independent concrete supply, fast ROI

Why LT-3.5 Was Chosen For This Project

After evaluating different concrete production options, the customer selected the LT-3.5 self loading concrete mixer truck based on a clear and practical decision logic.

Capacity Matchine The Project Scale

The LT-3.5 offers a 3.5m³ mixing capacity, which is well suited for small to medium construction projects. It allows the customer to:

- Produce concrete in batches that match daily on-site demand

- Avoid material waste caused by overproduction

- Maintain consistent concrete quality throughout the working day

Integrated Solution Compared With Traditional Methods

Compared with conventional concrete supply methods, the LT-3.5 provided a more efficient and economical a lternative:

- Versus ready-mix concrete supply

Eliminates dependence on external suppliers, transportation delays, and minimum order limitations.

- Versus small batching plants

Avoids high initial investment, complex installation, and fixed-site limitations.

By integrating self-loading, mixing, transporting, and discharging into one machine, the LT-3.5 enabled the customer to complete the entire concrete production process with one compact unit.

Adaptability To Local Construction Conditions

Construction sites in Honduras often involve uneven ground, unpaved roads, and limited working space. The LT-3.5 was selected because it can:

- Operate efficiently on narrow or rough job sites

- Move directly between material storage areas and pouring locations

- Maintain stable performance under continuous on-site operation

This combination of capacity suitability, system integration, and site adaptability made the LT-3.5 the most practical choice for this project.

On-site Working Video of Self Loading Concrete Mixer Truck In Honduras

To better demonstrate how the LT-3.5 performs under real construction conditions, the customer provided on-site working videos from the Honduras project. These videos clearly show how each major system operates together during actual daily use.

Self-loading Aggregates On Site

The video shows the hydraulic loading bucket collecting sand and gravel directly from the material stockpile.

This confirms the efficiency of the self-loading system and eliminates the need for external loaders.

Mixing Process During Operating

As the drum rotates, materials are mixed continuously while the machine is in operation.

The optimized drum and blade design ensure uniform mixing, even under mobile conditions.

Smooth movement between loading and pouring areas

The LT-3.5 moves steadily across uneven ground, demonstrating the effectiveness of the chassis and drive system in real job site environments.

Direct Concrete Discharge At The Construction Site

Concrete is discharged smoothly and accurately at the pouring location, showing how the integrated system supports efficient on-site concrete placement.

From a practical perspective, the Honduras project demonstrated that the LT-3.5 can help contractors achieve:

- Faster daily concrete output

- Lower labor and operational costs

- Stable and repeatable concrete quality

- Reliable performance in real construction environments

These results confirm the LT-3.5 as a practical and economically efficient solution for on-site concrete production.

Customer Feedback from Honduras

After a period of on-site operation, the customer provided direct feedback based on their actual construction experience with the LT-3.5 self loading concrete mixer truck.

The LT-3.5 works very well on our job sites. The self-loading function saves a lot of labor, and the mixing quality is stable.

We can produce concrete directly on site without depending on external suppliers, which gives us much better control over our schedule.

In addition to daily operation performance, the customer also highlighted several practical points:

- Smooth hydraulic response during loading and mixing

- Simple operation with a short learning curve

- Stable performance during continuous working hours

- Convenient communication and technical support

This feedback reflects the real concerns of contractors and investors when selecting construction equipment: reliability, ease of use, and practical cost control.

Rather than focusing on specifications alone, the customer’s experience confirms that the LT-3.5 performs consistently under actual job site conditions.

For buyers considering similar projects, this case demonstrates that the LT-3.5 is not a one-off solution, but a proven and repeatable choice for on-site concrete production.

Investment Value & ROI Analysis

From an investment perspective, the LT-3.5 self loading concrete mixer truck offers a clear and practical return model, especially for contractors and investors involved in small to medium construction projects.

Reduced Equipment and Operating Costs

By integrating multiple functions into one machine, the LT-3.5 significantly changes the traditional cost structure of concrete production.

With a single LT-3.5 unit, the customer can replace:

- A separate concrete mixer

- A wheel loader for aggregate loading

- Multiple transport and handling steps

This integration reduces:

- Initial equipment investment

- Fuel consumption across multiple machines

- Maintenance and coordination costs

Lower Dependence on Labor and External Supply

Labor and concrete supply are two major cost variables in construction projects. The LT-3.5 helps control both:

- One operator can manage the entire concrete production process

- On-site production eliminates reliance on ready-mix suppliers

- Project schedules become less vulnerable to supply delays

As a result, daily operating expenses become more predictable and controllable

Faster Project Turnover and Capital Efficiency

The ability to produce concrete on demand allows contractors to:

- Adjust production volume based on actual site needs

- Avoid waiting time caused by delivery or batching plant scheduling

- Maintain steady progress across multiple work stages

Faster execution improves project turnover speed, the Honduras case demonstrates a typical investment logic:

- Stable daily utilization across different job sites

- Flexible use for foundations, slabs, and structural elements

- Long-term equipment value beyond a single project

For many customers, the LT-3.5 becomes a core revenue-generating asset, rather than a project-specific machine.

A Balanced Investement Decision

The LT-3.5 is not positioned as a low-cost shortcut, but as a balanced investment combining productivity, reliability, and flexibility.

This approach helps contractors and investors achieve sustainable returns under real construction conditions.

Main Components of LT-3.5 Self Loading Concrete Mixer Truck

The performance of a self loading concrete mixer truck is not determined by a single parameter, but by how multiple systems work together under real construction conditions. The LT-3.5 is designed as an integrated concrete production systems, with each major component optimized for efficiency, reliability, and long-term operation.

Self-loading System – Efficient and Accurate Material Feeding

The self-loading system is the starting point of the entire concrete production process.

The LT-3.5 is equipped with a hydraulically driven loading bucket, allowing the operator to load aggregates directly from stockpiles without the need for additional loaders.

Key design advantages:

- High-strength bucket structure for repeated loading of sand and gravel

- Smooth hydraulic control for stable and precise material feeding

- Efficient loading cycle that reduces idle time between batches

By integrating the loading system with the mixing process, the LT-3.5 ensures continuous material flow, which is critical for maintaining productivity on site.

Mixing Drum & Mixing System – Uniform Mixing Under Mobile Conditions

The mixing system is the core of concrete quality.

The LT-3.5 uses a purpose-designed mixing drum, optimized for on-site concrete production rather than stationary plant conditions.

Structural characteristics:

- Optimized drum geometry for consistent material circulation

- Internal mixing blades arranged to improve lifting and folding action

- Stable drum rotation during both mixing and traveling

This design allows the machine to mix concrete uniformly even while moving, ensuring consistent concrete quality from batch to batch.

Water Supply & Control Systm – Stable Concrete Quality Control

Accurate water control is essential for concrete strength and workability. The LT-3.5 is equipped with an on-board water supply system, enabling the operator to add water directly during the mixing process.

Practical benefits:

- Controlled water addition improves mix consistency

- Reduces the risk of overwatering or uneven mixing

- Ensures repeatable concrete quality across different batches

This system is particularly valuable for on-site operations where external water supp;y conditions may vary.

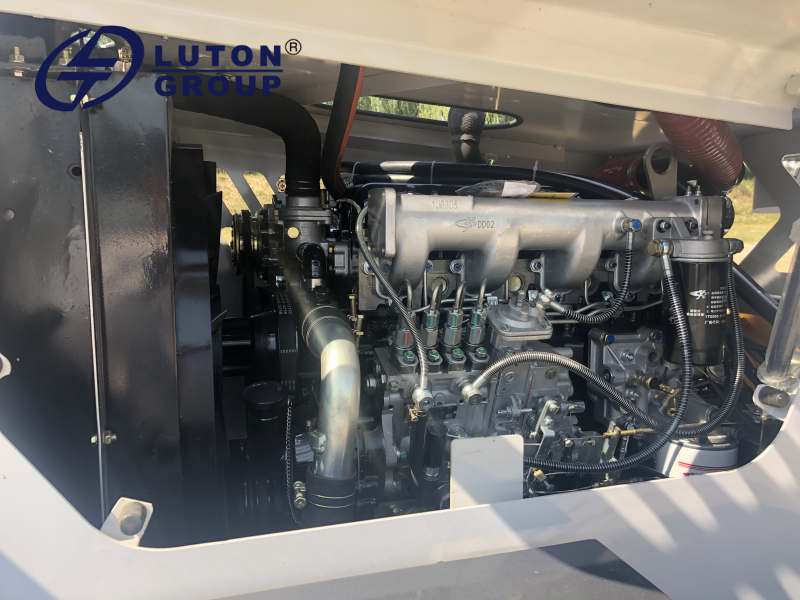

Hydraulic System – Power Multiple Functions Simultaneously

The hydraulic system acts as the central power unit of the LT-3.5, driving key operations such as:

- Bucket lifting and self-loading

- Drum rotation and mixing

- Steering and auxiliary functions

The system is designed for stable multi-function operation, allowing several actions to run smoothly at the same time without performance loss. This is crucial for maintaining productivity during continuous working cycles.

Chassis, Drive & Mobility System – Built for Real Job Site Conditions

To adapt to demanding construction environments, the LT-3.5 features a reinforced chassis and reliable drive system.

On-site advantages include:

- Strong load-bearing capacity during full drum operation

- Good traction on uneven or unpaved roads

- Stable driving performance between loading and pouring locations

This mobility enables the machine to function as a true on-site concrete production unit, rather than being restricted to a fixed position.

Operation & Control System – Simple Efficient and Operator-Friendly

Ease of operation directly affects productivity and labor cost.

The LT-3.5 is designed so that one operator can complete the entire concrete production process, from loading to discharging.

Operational highlights:

- Intuitive control layout

- Short training time for new operators

- Reduced dependence on skilled labor

This simplicity allows contractors to deploy the machine quickly and efficiently, even in regions with limited access to experienced operators.

Each of these systems plays a specific role, but it is their coordinated operation that defines the real value of the LT-3.5. Together, they allow the customer in Honduras to achieve:

- Stable concrete quality

- Continuous on-site production

- Lower labor and operating costs

- Reliable performance under practical working conditions

Why Choose LUTON Self Loading Concrete Mixer Trucks

Choosing the right self loading concrete mixer truck is not only about specifications, but also about manufacturing capability, quality control, and long-term support.

As a professional manufacturer of self loading concrete mixer trucks, we focus on delivering equipment that performs reliably under real construction conditions.

Manufacturing and Quality Control

- Standardized production processes and strict inspection procedures

- High-quality structural components designed for long-term operation

- Continuous optimization based on feedback from global projects

Each machine is tested before delivery to ensure stable performance in overseas markets.

Global Export Experience

Our self loading concrete mixer trucks have been successfully delivered to 80+ countries and regions, serving contractors and investors in diverse construction environments.

This export experience allows us to :

- Understand different market requirements

- Provide suitable configurations for local conditions

- Offer practical solutions based on real project experience

After-Sales Support and Technical Service

We provide ongoing support beyond equipment delivery, including:

- Technical guidance for installation and operation

- Spare parts supply and maintenance support

- Responsive communication for troubleshooting and service

Our goal is to help customers achieve long-term, stable operation and profitability.

Export Cases Of LUTON Self Loading Concrete Mixer

Get Price, Video & Technical Details of LT-3.5

If you are considering a self loading concrete mixer truck for your construction project or investment, the LT-3.5 offers a proven solution backed by real project experience. There are also other optional models ( from LT-1.2 to LT-6.5 ) for your special application scenarios.

Contact us to receive:

- Latest LT-3.5 price and configuration options

- Full on-site working videos from different countries

- Detailed technical specifications and machine drawings

- Project-based recommendations tailored to your local market

| Model | LT-1.2 | LT-1.8 | LT-2.0 | LT-2.6 | LT-3.5 | LT-4.0 | LT-5.5 | LT-6.5 |

| Capacity (m3/h) | 4.8 | 7.2 | 8.0 | 10.5 | 14 | 16 | 22 | 26 |

| Engine | YUNNEI | YUCHAI 4102 | YUCHAI 4102 | YUCHAI 4102 | YUCHAI 4105 | YUCHAI 4108 | FAW XICHAI 6110 | WEICHA 6105 |

| Rated Power | 58kW | 78kW | 78kW | 78kW | 85kW | 91kW | 92-110kW | 92-110kW |

| Gear | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back |

| Oil Tank | 16L | 16L | 16L | 16L | 16L | 16L | 16L | 16L |

| Water Tank | 400L | 500L | 500L | 500L | 620L | 660L | 860L | 1465L |

| Water Supply | Time Relay | Time Relay | Time Relay | Time Relay | Time Relay | Time Relay | Time Relay | Time Relay |

| Drum Rotate | 270° | 270° | 270° | 270° | 270° | 270° | 270° | 270° |