Self loading concrete mixer parts refer to the main components of various functional systems for self loading concrete mixer truck. The quality of these parts directly affects the performance and lifespan of the entire equipment. Good self loading concrete mixer parts are the key guarantee for efficient production and stable operation of the equipment. Why do the self loading mixer trucks produced by LUTON GROUP have stable performance and superior quality? One of the reasons is that they have a variety of high-grade, reliable and durable components.

Self loading concrete mixer parts can be classified into seven main parts according to different system functions.

- main power system components: diesel power engines

- driving system components: chassis, frames, front and rear axles, etc.

- self loading system components: feeding hopper, loading arm, etc.

- weighing system parts: position sensors and time relays, etc.

- mixing system parts: mixing tank, mixing blades, etc.

- hydraulic system parts: main oil pump, hydraulic cylinder, hydraulic valve, hydraulic motor, reducer, etc.

- electrical control system components: power supply, controller, LCD screen, etc.

Main Configurations of Self Loading Concrete Mixer

| Equipment Model | LT-1.2 | LT-1.8 | LT-2.0 | LT-2.6 | LT-3.5 | LT-4.0 | LT-5.5 | LT-6.5 |

| Discharge Capacity | 1.2m3 | 1.8m3 | 2m3 | 2.6m3 | 3.5m3 | 4m3 | 5.5m3 | 6.5m3 |

| Output/Capacity | 4.8m3/h | 7.2m3/h | 8m3/h | 10.5m3/h | 14m3/h | 16m3/h | 22m3/h | 26m3/h |

| Engine Model | YUNNEI supercharged engine 58KW | Yuchai 4102 Turbo-charged 78KW | Yuchai 4105 Turbo-charged 85KW | Yuchai 4108 Turbo-charged 91KW | FAW XICHAI 6110 Turbo-charged 92KW~110KW | Weichai deutz 6105 Pressure boost 92KW~110KW | ||

| Gear | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back | 4 forward 4 back |

| Oil tank | 16 liters | 16 liters | 16 liters | 16 liters | 16 liters | 16 liters | 16 liters | 16 liters |

| Water supply | Time relay | Time relay | Time relay | Time relay | Time relay | Time relay | Time relay | Time relay |

| Drum rotate | 270º | 270º | 270º | 270º | 270º | 270º | 270º | 290º |

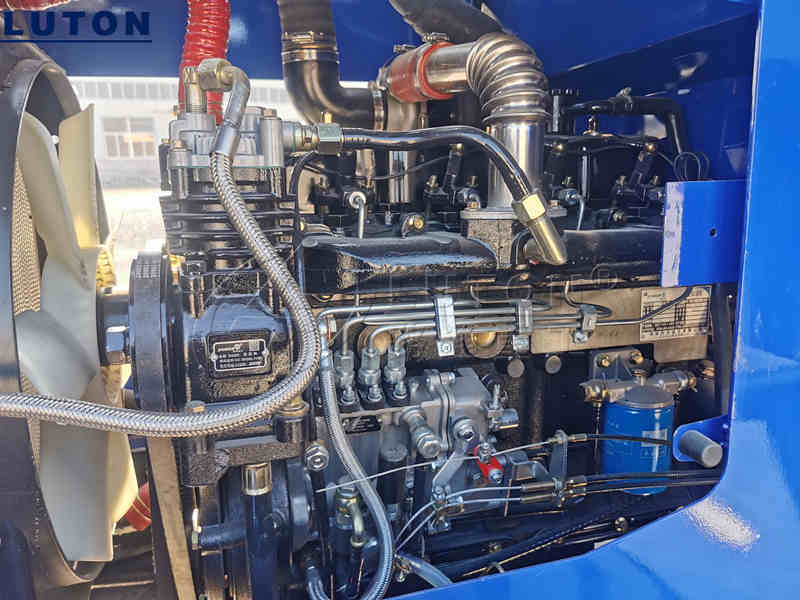

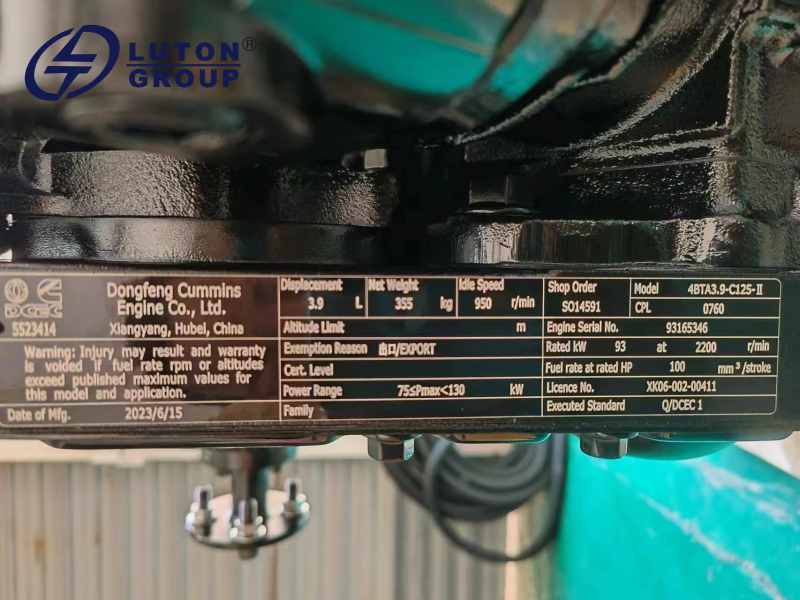

Diesel Engine

As the power source of the entire equipment, the performance of the diesel engine directly affects the power and fuel economy of the self loading mixer truck. The engine also ensures the normal operation of the self loading mixer truck by driving components such as the mixing tank and the driving system. According to the different needs of customers, LUTON GROUP configurates different brands and models of diesel engines for various self loading mixer models. There are Cummins from the USA, Weichai and Yuchai from China, with output power ranging from 58kW to 110kW.

Driving System Parts

The driving system includes front and rear axles, chassis, tires, and other components. These parts enable the whole self loading concrete mixer to drive stably on the road. The self loading mixer trucks of LUTON GROUP are all four-wheel drived. In order to meet different requirements, there are also multiple options for the number of wheels, including front 2 and rear 2, front 4 and rear 2, etc.

Parts In Self Loader System

Self loading system is the unique part of self loading mixer trucks. It can automatically complete the feeding process, reduce manual operations, and improve work efficiency. The self feeding device usually consists of feeding hopper, feeding boom and other components. They cooperate to lift the concrete raw materials from the ground to the mixing tank.

In detail, under the instructions of the controls system, the feeding hopper and the loading arm are driven by the hydraulic power system. LUTON GROUP provides different types of feeding hoppers for loading different materials, including bucket type ( for stones and sand ) and hopper type ( for cement and other powders). The steel structure of the feeding arm is hard and streng sufficiently to lift a full hopper of raw materials into the mixing drum at once.

Self Loading Mixer Tank

The mixing tank is the core component of a self loading concrete mixer truck. It is equipped with stirring blades inside, which mix cement, sand, stones and other materials evenly through rotation and stirring. The volume and mixing efficiency of the mixing tank directly affect the production capacity of the mixer truck and the quality of the concrete.

LUTON GROUP has mixing tanks with different production capacity. The mixing tank has the function of forward and reverse rotation. The bottom of the tank is supported by a rotatable base, with a rotation angle range covering 0-270°, greatly enlarging concrete pouring area.

The mixing tank is equipped on a jacking equipment. After the mixing process, the discharge port end of the tank can be raised for easy discharge. The tank body is made of manganese steel material with a thickness of 4.75mm.

Self Loading Mixer Parts In Hydraulic System

The hydraulic system is mainly responsible for rotation of the mixing tank, lifting and lowering the self loader device, and other actions. They are hydraulic pumps, hydraulic cylinders, hydraulic valves and other components. They can control and regulate various actions through the transmission of hydraulic oil.

LUTON GROUP self loading mixer truck adopts the American plunger variable motor and reducer of domestic military brand. These parts ensure stable output power of the hydraulic system and drive various executing components to complete each stage of the process. The hydraulic oil pipe adopts a drainage method with a longer service life.

Self Loading Concrete Mixer Parts – Electrical System

The electrical system is one of the auxiliary systems of the self loading mixer truck. It takes charge of controlling the operation of the entire equipment and monitoring various parameters. It usually consists of components such as power supply, controller, sensors, etc.

Vulnerable Parts of Self Loading Concrete Mixer Truck

Hydraulic system components are prone to wear and tear or damage due to long-term or improper use. Usually they are hydraulic pumps, hydraulic motors, hydraulic cylinders, hydraulic valves, etc., .

Mixing device components, such as mixing blades, mixing shafts, bearing, etc., are prone to wear or damage during the mixing process. The mixing blade is one of the most important components in the mixing system, with fast speed, high load. Due to the need to withstand the impact and friction of concrete, it is prone to wear, fracture, and other phenomena.

Tires and suspension system components, such as tires, shock absorbers, steel plates, etc., are prone to wear or damage due to long-term or improper use.

Lubrication system components, such as lubricating oil pumps, lubricating oil filters, etc., are easy to wear or damage due to long-term or improper use.

Electrical system components, such as cables, wires, controllers, etc., are inclined to damage due to aging or improper use.

Seals, such as oil seals, gas seals, etc., are prone to damage due to aging or improper use.

In order to ensure the normal operation and extend the service life of the self loading mixer truck,these vulnerable parts should be inspected and replaced regularly. Meanwhile, during use, attention should also be paid to the maintenance and upkeep of the equipment to avoid damage caused by improper use.

In short, the main components an vulnerable parts of the self loading mixer truck together constitute this efficient and practical construction equipment. Understanding its structure and characteristics can help to better use and maintain equipment, improve work efficiency and construction quality.

LUTON Products Gallery

Self Loading Concrete Mixer for Sale

LT1.2 Self Loading Concrete Mixer Truck

LT6.5 Self Loading Concrete Mixer

LT4.0 Self Loading Concrete Mixer

LT2.6 Self Loading Concrete Mixer

LT2.0 Self Loading Concrete Mixer

5.5m3 Self Loading Concrete Mixer

3.5m3 Self Loading Concrete Mixer