Self loading concrete mixer LT-4.0 of LUTON GROUP successfully boosted a rural road upgrading project in Kenya. Flexibly and efficiently, LT-4.0 completed the whole concrete treatment process in a continuous way.

| Model | LT-4.0 |

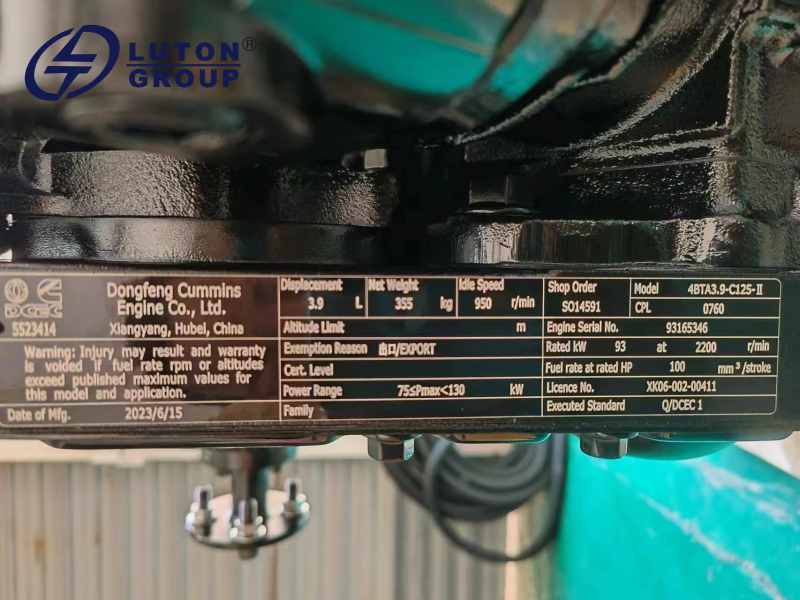

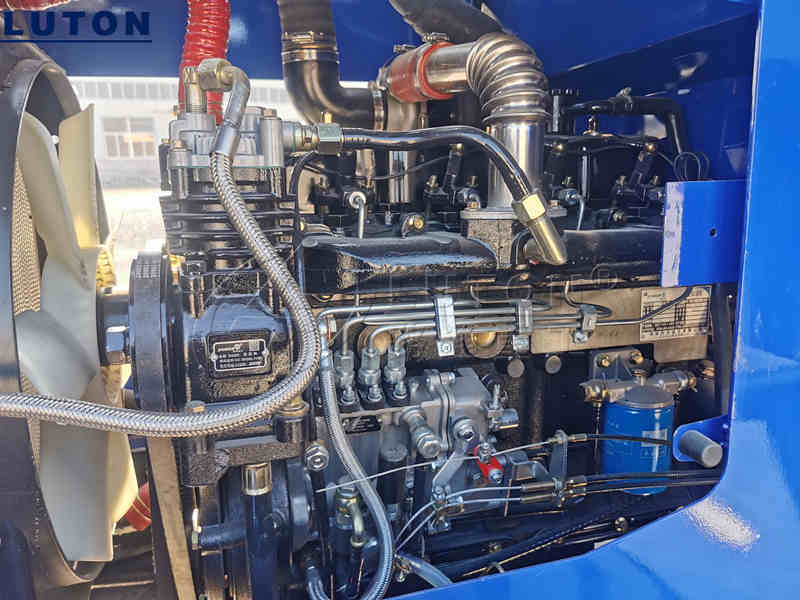

| Engine Brand | CUMMINS 97kW |

| Feeding Capacity | 6800L |

| Discharge Capacity | 4000L |

| Output Capacity | 20m³/h (4m³/h) |

| Gear | 2 forward 2 back |

| Wheelbase | 2480mm |

| Max. Gradeability | 30° |

| Max. Speed | 35km/h |

Project Background Of Kenyan Rural Road Project

This project is for the upgrading of the rural road network in Kisii County, Kenya. The length of the whole rural roads is about 50km, with a total demand for concrete of approximately 12,000 cubic meters.

Project Challenge

- Complex Terrain

Many hills and muddy sections make it difficule for traditional mixer trucks to pass through.

- Power Shortage

There is no stable power supply in remote areas, making it impossible to set up a fixed concrete batching plant.

- Manpower Limitation

Skilled local operators are scare, and highly automated equipment is required.

- Cost Sensitivity

The project budget is limited, and it is required that both equipment procurement and operation and maintenance costs be low.

Requirements Analysis Of The Kenyan Project

The Kenyan contractor put forward the core requirements:

- Equipment Adaptability

Four-wheel drive capability, climbing slope no less than 30°, the minimum turning radius no more than 7m, suitble for village roads width 3m to 4m.

- Self Sufficiency

It can independently complete the loading and mixing of sand and gravel without the need for an external loader.

- Low Maintenance

It can withstand high humidity and dusty environments, and has a long replacement cycle for components.

- Cost performance

The procurement cost is no more than $30,000, and the comprehensive construction cost is lower than that of the traditional concrete batching plant + transport vehicle model.

Selection Process Of LT-4.0 Self Loading Concrete Mixer

The whole selection process of this self loading concrete mixer Kenya includes four main steps. By initial selection of products, technical vertification, cost esimation, our Kenyan customer finally decided this LT-4.0 model for their road upgrading project.

Step1 Initial Model Selection

Through further communication with the customer, our professional consultant recommended this LT-4.0 for the optimal model.

Actually, the customer formerly compared with some different models of other brands from India and Italy. The LT-4.0 with all-terrain design, low maintenance cost and reasonable price, is obviously superior to other products.

Step2 Technical Vertification of LT-4.0

First of all, for every product delivered to customers in the best condition, LUTON products will undergo a series of rigorous tests before they are shipped. Also, our Kenyan customers also conducted field tests as soon as they received the equipment.

In Kisey County, a muddy slope (with a gradient of 30°) was simulated. Our LT-4.0 was fully loaded with concrete and climbed steadily without slipping.

In addition, the loading efficiency of the hydraulic bucket is test as 2 minutes and 15 seconds per bucket ( design value is less than 3 minutes), exceeding customer expectations.

Forthermore, for maintenance evaluation, the key components (hydraulic pump, filter element, etc.) are designed to be universal, with a compatibility rate of 80% with common local construction machinery parts.

The open hydraulic pipeline layout reduces the troubleshooting time by 40% compared with competing products.

Step3 Cost Estimation

| Cost Item | LT-4.0 | Traditional Solution (Mixing Plant + 6 Trucks) |

| Equipment Purchase | $28,900 | $330,00 |

| Fuel Consumption | $0.8/m³ | $1.2/m³ |

| Labor Cost | 1operator + 1worker | 3 worker for the mixing plant + 6 truck drivers |

Step4 Decision Confirmation

Our Kenyan customer finally purchased two sets of LT-4.0 self loading concrete mixer for their rural road project. The reasons are obviously:

- The all-terrain capability meets the on-site requirements, and the procurement cost is only 29% of the traditional solution.

- The modular design is adapt to local maintenance capabilities and reduces the risk of downtime.

- LUTON promises to respond to after-sales issues within 48 hours and dispatch engineers to provide on-site training.

Project Implementation And Operation

Localization Adaptation

In response to the high humidity environment in Kenya, LUTON installed anti-rust coatings on the hydraulic system.

The operation interface has added Swahili tags to simplify the operation process.

Training And Support

Engineers from LUTON went to Kenya for an operation training, focusing on teaching the operation process and the maintenance of the whole set.

In advance, a WhatsApp technical support group to respond to operational issues in real time was established.

Construction Effect

By the two sets of LT-4.0, the average daily concrete pouring is 320m³ (8h working daily), which is completed about 38 days, 18 days ahead of the schedule.

Customer Feedback

“The independent operation capability of LUTON LT-4.0 self loading mixer truck has completely transformed our construction mode in remote areas. The four-wheel drive system performed well during rainy season, and the maintenance cost was 30% lower than expected.”

Export Case Of LUTON Products

LT3.5 Self Loading Concrete Mixer Exported to Vanuatu

LT1.2 Self Loading Concrete Mixer in Zimbabwe

LT1.8 Self Loading Concrete Mixer Truck to Serbia

LT4.0 Self Loading Concrete Mixer Truck Sold In Cameroon

LT3.5 Self Loading Concrete Mixer Sold to Indonesia