Self loading cement mixer, also known as the official name of self loading concrete mixer (truck), has been used more and more in different construction projects. Combined with multiple functions, self loading cement mixer, with flexible and lightweight body, convenient operation, efficientt and poweful working performance, wins more and moer praise in construction industry.

Flexible Suitability to Various Construction Sites

Efficient Performance of Automatic Operation

Multiple Functions & Cost-saving Choice

Model Show Of LUTON Self Loading Cement Mixer

LT-1.2

| Model Output | LT-1.2 |

| Discharge Output | 1.0m3 |

| Output Capacity | 10m3/H |

| Engine Model | Yunnei Supercharged |

| Fuel Consumption | 3L/H |

LT-2.0

| Model Output | LT-2.0 |

| Discharge Output | 1.5m3 |

| Output Capacity | 12m3/H |

| Engine Model | Yuchai 4102 |

| Fuel Consumption | 3.6L/H |

LT-3.5

| Model Output | LT-3.5 |

| Discharge Output | 3.0m3 |

| Output Capacity | 18m3/H |

| Engine Model | Yuchai 4105 |

| Fuel Consumption | 3.6L/H |

LT-4.0

| Model Output | LT-4.0 |

| Discharge Output | 4.0m3 |

| Output Capacity | 20m3/H |

| Engine Model | Yuchai 4108 |

| Fuel Consumption | 6.5L/H |

LT-6.5

| Model Output | LT-6.5 |

| Discharge Output | 6.0m3 |

| Output Capacity | 30m3/H |

| Engine Model | Weichai Deutz 6105 |

| Fuel Consumption | 7.0L/H |

LTP-2.0

| Model Output | LTP-2.0 |

| Discharge Output | 1.6m3 |

| Output Capacity | 19.2m3/H |

| Engine Model | Yunnei 4102 |

| Fuel Consumption | 3.5L/H |

What Is Self Loading Cement Mixer

Self loading cement mixer truck is a type of efficient and economical concrete machine. The name is from its main functions – loading, mixing, unloading and transporting on site. Not like common concrete mixing machine, self loading cement mixer, can feed materials by itself through a powerful arms and loader mounted in the front of the mixer truck. Such flexible and powerful loading equipment to complete concrete task only requires the control of the levers and the buttons in the cab. In this way, treatment of concrete on sites doesn’t need workers, loaders and conveyors to assist in loading and transporting materials any more, saving a lot of manpower and equipment cost for users.

Application Area Of Self Loading Cement Mixer

Compact self loading cement mixer with small and light body is suitable for most of construction sites, including small-sized residential housing, road paving, ditch construciton, etc. Especially it is suitable for all kinds of narrow sites and mountain sites thanks for its two-way driving function and the strong climbing ability.

Advantages Of LUTON Self Loading Cement Mixer

- High quality tires from famous brand with three years warranty of 300,000 kilometers.

- The oil cylinder is equipped with a protective cover to extend the service life.

- Automatic hydraulic material tank, operating in the cab, improve the production efficiency.

- Direct disposable feed and smooth feeding improve production efficiency.

- The truck head is reinforced by groove steel. Ruili brake system is built in brake pump, which prevent damage and prevent dust from entering the brake system.

- Rayleigh dryer stainless steel air cylinders to better protect the brakes.

- Fully sealed turbo-worm turntable, warranty for 5 years.

- Air pre-filter, separate the dust from the air to protect the engine.

- Self-developed hydraulic suction water pump to reduce the failure rate.

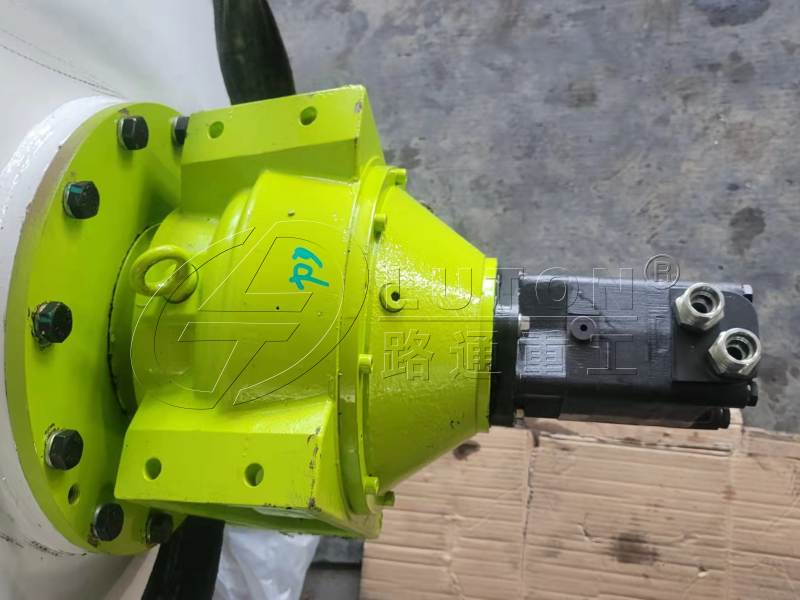

- Military quality reducer warranty for three years. Plunger type transformer motor 20rpm, warranty for three years.

What Are The Main Components Of Self Loading Cement Mixer

The whole self loading cement mixer system is consisted of nine function systems, including loading system, measuring system, mixing system, unloading system, truck propelling system, main transmission system, hydraulic system, water system, lubrication system and so on.

In every system, the components cooperating with each other and finally fulfill the whole working process of self loading cement mixer truck. Some of the main components deserve our attention.

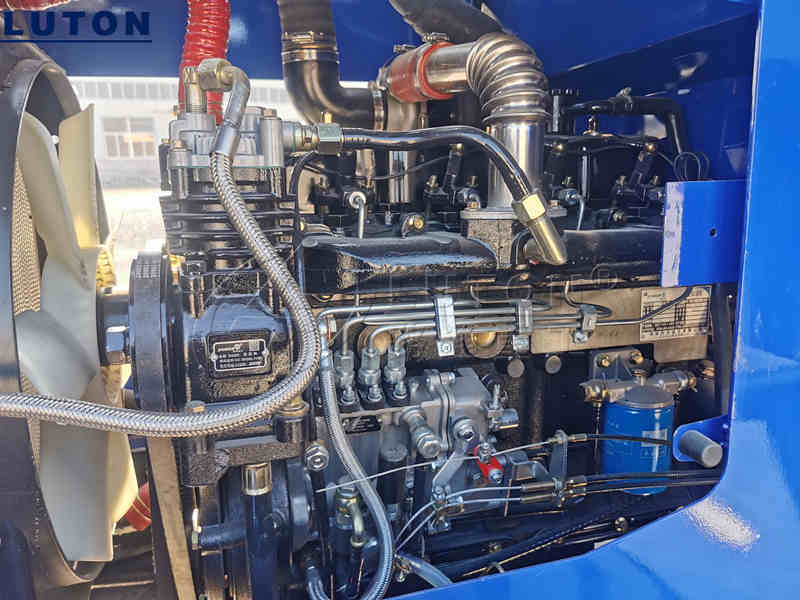

Diesel Engine

The power origin, diesel engine, is the heart of a self loading cement mixer truck. It provides a power source for the normal operation of the whole system, on the one hand for the monvement of the truck chassis, on the other hand for mechanical power of the functional operation in all parts systems.

LUTON GROUP self loading mixer is configurated with Chinese leading brands Yuchai and Weichai diesel engine as the whole power origin.

Reducer

Reducer is the key unit of the transmission system, which convert the kinetic energy with high speed and small torque into that of low speed and large torque for the truck chassis propelling system as well as mixing drum system.

Mixing Drum or Mixing Pan

Mixing drum and mixing pan are the core device of the whole self loading mixer system. For the mixing drum, it is installed on a counterweight on a heavy duty saddle, which can be hydraulically slewed at 0-270°.

Driving Cab

Control system is installed in the driving cab. Besides control levers and buttons, there are also LCD which displays realtime working situation and data.

Loading Shovel

The loading shovel is driven by hydraulic power system. The bucket moves fast and steady, The upper arm is equipped with a stroke switch, which starts the weighing function after triggering.

Water Tank

Water tank provide water for concrete mixing process and cleaning function.

How Does Self Loading Cement Mixer Work

Self loading cement mixer is actually a flexible concrete mixing tool. We can regard it as a small set of mobile concrete batching plant. Its working process can be simply described as the following steps: materials loading, weighing, mixing, unloading and transporting.

1. Self Loading

In the self loading step, the operator can easily control the bucket feeding, lifting and unloading by manipulating the lever to complete the whole self-loading process. This series of action is actually done by the hydraulic power to push and draw the piston in each hydraulic cylinder. When the hopper is lifted in place and the unloading door is opened, the material falls into the mixing drum, and a complete feeding process is end.

2. Automatic Weighing

The weighing step is actually completed in the bucket lifting process.

Specifically, when the hopper is lifted to the horizontal position by hydraulic arm, the stroke switch installed on it is triggered, and the rapic weighing program is started. The weighing data will be transmitted to the LCD screen in the cab in the first time, and the operator can adjust the material loading amount accordingly.

3. Self Mixing

When cement, sand, water and other materials are all loaded into the mixing drum, the mixing process is started. The double-cone mixing drum has double-spiral mixing screws and convex bottom, which ensure the evenly and thoroughly mixing job. The drum rotation is achieved by gear pump and cycloidal hydraulic motor in open circuit with a manual electric valve in the driver’s cabin and in the rear of the mixer.

4. Unloading

When it comes to the unloading step, the drum rotates reversely controlled by the operator and the concrete product is unloaded from the drum.

The drum rises to horizontal position through two double-acting jacks. The counterweight mounted on the heavy duty saddle can be hydraulically slewed at range of 0-270° and automatically locked by a hydraulic brake. The unloading chunte, which can be rotated by 90° , is tilted by a manually adjustable handle or an automatic buttom. Removable chutes ensure unloading directly through the hopper.

All these designs are aiming to flexibly meet concrete dischargement at different angles.

Operation of Self Loading Cement Mixer

It is very necessary to perform the proper routine maintenance of the equipment during the long operation process.

1. Check The Oil Radiator And Reducer Hydraulic Oil Level

The hydraulic driving system is one of the core parts of the self loading mixer. In order to ensure the normal operation of the mixer and mixing tank, it is necessary to check the oil radiator and reducer hydraulic oil level before every time of the vehicle start.

2. Ensure The Cleanliness Of The Hydraulic Oil

In the process of self loading cement mixer working, we also need to ensure the cleanliness of the hydraulic oil. Avoid the existence of dust and moisture and other pollution of the system hudraulic oil, which will cause the system can not work properly.

3. Check The Water Amount

The water amount of the water supply system is generally at three-quarters of the water tank.

During the propelling process, each valeve in the waterway system should be closed, so as not to affect the braking performance of the self loading cement mixer. The sealing of the sysem should be checked regularly, and threaded sealant is required to the parts after disassembly and repair.

4. Check The Bolts

The mixing cylinder of the self feeding mixer should be checked the bolts of tank and other parts to ensure there is no lossening phenomenon. And before each driving, the lubrication of the carrier wheel and roller path should be checked.

5. Clean The Residual Cement

At the end of each construction, the outer surface of the vericle and the residual material inside the tank must be cleaned to prevent the concrete from setting inside and outside the tank.

6. Maintain The Main Components

Strengthen the periodic maintenance of the engine, gear box and axle. If it is not used for a long time, the water tank should be cleaned.

7. Change Oil Regularly

Engin oil and gear oil should be changed every 1,200 hours. Working continuously for 7 days, the oil filter should be cleaned. The air filter should be cleaned every 100 hours.

8. Check The Pressure Of The Tire air

Check the tire air pressure before leaving the mixer truck. Timely fill gas and lift the air pressure to the standard value.

9. Lubricate The Axles and Shafts

Inject with butter into the front and rear axle connection shaft pins and each cylinder shaft sleeve, front and rear drive shaft after finishing the work everyday.

Good using habits are good to extending the service life of self loading cement mixer.

Products Gallery

Self Loading Concrete Mixer for Sale

LT1.2 Self Loading Concrete Mixer Truck

LT6.5 Self Loading Concrete Mixer

LT4.0 Self Loading Concrete Mixer

LT2.6 Self Loading Concrete Mixer

LT2.0 Self Loading Concrete Mixer

5.5m3 Self Loading Concrete Mixer

3.5m3 Self Loading Concrete Mixer