LT2.0 self loading concrete mixer is a small model of LUTON self loading concrete mixing equipment family, focus on easy and economical concrete solutions to small or medium scaled construction projects.

| Capacity | 8 batches/12m3 per hour |

| Speed | 35km/h |

| Fuel Consumption | 3.6L/H |

With small and light body, multiple automatic operation, high efficient performance, LT2.0 now is common seen in various construction sites, including rural residential construction, urban high-rise construction , rough-terrain construction, bridges, dams, docks, tunnels, roads, etc., just like a kind of mini mobile concrete batching plant, playing an important role in modern concrete construction sites.

Parameters of LUTON LT2.0 Self Loading Concrete Mixer

| Equipment Model | LT-2.0 |

| Discharge Capacity | 2m3 |

| Output/Capacity | 12m3/h |

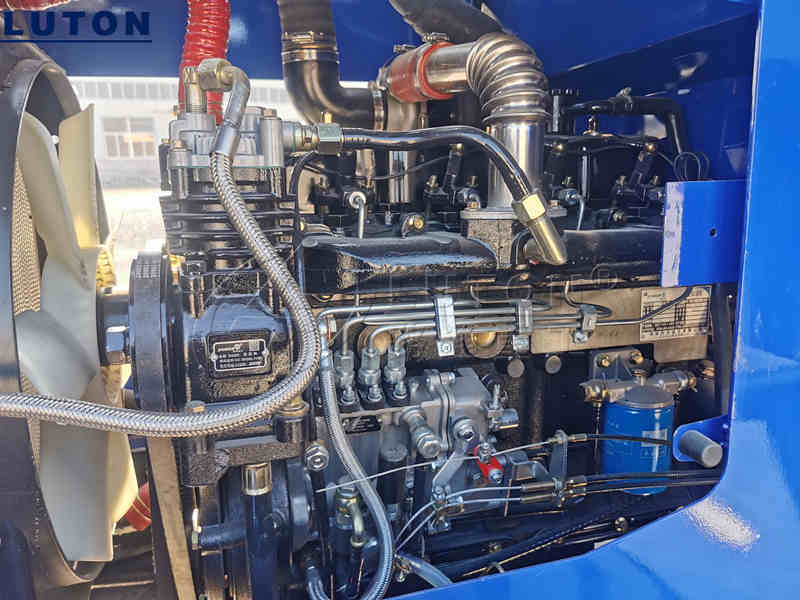

| Engine Model | Yuchai 4102 Turbo-charged |

| Rated Power | 78KW |

| Gear | 4 forward 4 back |

| Oil Tank | 16 liters |

| Water Tank | 500L |

| Water Supply | Time Relay |

| Overall dimensions(L*W*H) | 7300*2650*3750 |

| Curb Weight (kg) | 6500 |

| Drum Rotate | 270º |

*LT-2.0 self loading mixer truck of LUTON provides four optional standards configurations for your construction desire. For more speciall requirements, you can also contact with our professional consultants to get customization.

Advantages Of LT2.0 Self Loading Concrete Mixer

Small & Light

Small size, light weight, flexible and easy to transport, adapt to even narrow construction space.

Multiple Functions

With automatic loading, weighing, mixing, unloading and transportation functions, a set of 2.0 machine can achieve a variety of automatic operation, equivalent to a collection of five different kinds of equipment.

Cost-saving

Multiple automatic functions need only one operator and 1-2 workers, without too much labor and equipment requirement, saving costs of manpower and equipment.

High Efficiency

LUTON LT-2.0 self loading concrete mixer can produce 12m³concrete per hour. According to the 8-hour working system per day, the daily output is 96m³concrete material. Compared with the traditional mixing equipment, the output efficiency is higher, which saves more construction time for construction organization.

Flexible & stable

Equipped with four-wheel drive chassis and off-road tires, coupled with scientific articulated body design, this mixing loader truck can walk freely on the rugged mountain road. Even the 30° slope, the self loading mixer can easily moved on it. Flexible and stable, it is a good helper of mountain operation.

Durable & Convenient

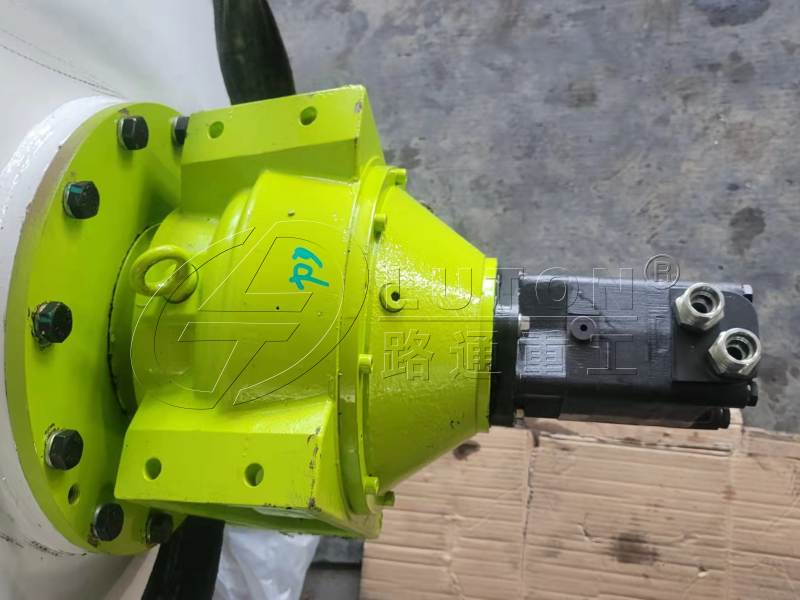

Enlarging and widening the fully sealed imported turntable, with a 5-year warranty (the cycloidal motor drives the turbine worm). High level excavator cab with high safety factor (frame structure anti-sideways) and luxury engineering shock-absorbing seat. Brake pump from Ruili Group, double pump air brake, safe and stable braking (1 year warranty).

Technical Features Of LT2.0 Self Loading Concrete Mixer

- Using China’s famous brand of diesel power equipment, for both the frame walking and various actions of mixing drum, which provides a strong and stable source of power. The powerful diesel engine is the core part of the whole self-loading concrete mixing truck.

- Hydraulic unit is supported by world’s famous brands with high quality and excellent performance, stronger power and lower fuel consumption.

- In addition to the 360°self rotation function of the concrete mixing drum, there are also a 0~270°horizontal rotation range, providing optional unloading position, so that the mixing cylinder can flexibly adapt to different concrete unloading sites. The rotating power of the mixing drum is taken from the strong diesel source at the bottom of the chassis, and through the deceleration device and hydraulic transmission to achieve smooth and stable control of speed and direction changing and other.

- The loading arm is controlled by a special hydraulic control system to realize a fast and stable loading and unloading process, which is the core of the function. The main equipment of the hydraulic system is provided by the international famous brands.

- The fast and sensitive weighing unit is located at the side of the loading arm. It adopts the way of time relay to quickly and precisely weigh the raw materials in the hopper and transmit the data to the display screen in the driving cab, which realize the real-time observation.

- The automatic water loading function of self loading mixer is realized by a special water supply system. The automatic water supply system centered on the water pump can provide continuous water supply for the entire production process.

- The control and display ends of all operations are integrated in the driving cab, and the operator can easily monitor and manipulate the entire production process in a wide view cab.

Gallery of LUTON Self Loading Concrete Mixer

Export Cases of LUTON Self Loading Concrete Mixer

LT3.5 Self Loading Concrete Mixer Exported to Vanuatu

LT1.2 Self Loading Concrete Mixer in Zimbabwe

LT1.8 Self Loading Concrete Mixer Truck to Serbia

LT4.0 Self Loading Concrete Mixer Truck Sold In Cameroon

LT3.5 Self Loading Concrete Mixer Sold to Indonesia