Diesel self loading mixer truck to Eswatini is a successful export case of LUTON construction equipment. This is a part of a series purchase items of the client, who takes charge of several construction projects of local infrastructures, including a small-sized residential community, a school sports stadium and a road building in mountain area. The LT3.5 will assist his group to complete these construction tasks.

| Model | LT-3.5 |

| Output Capacity | 14m³/h |

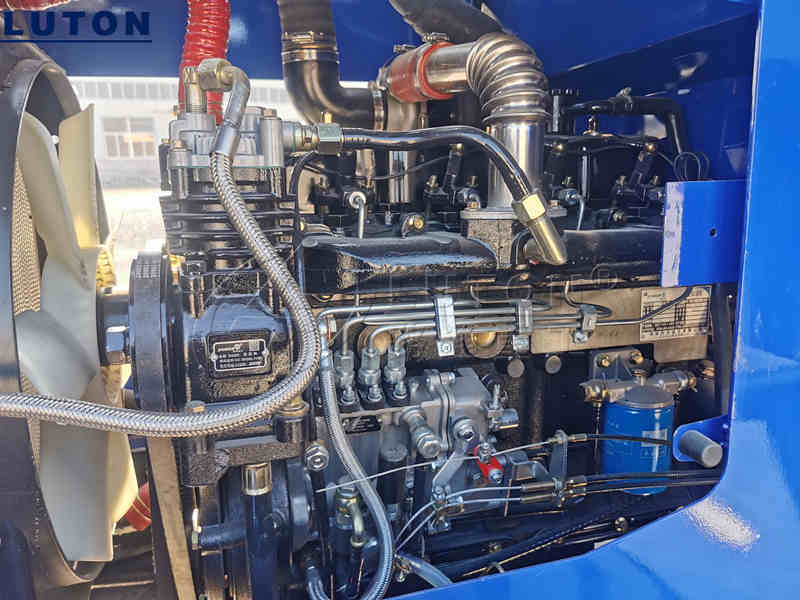

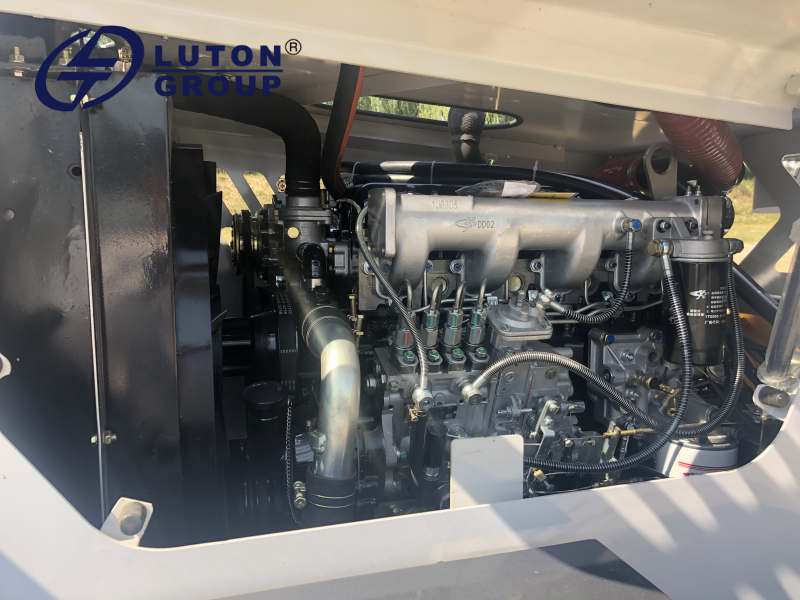

| Engine Model | 85 kW Yuchai 4105 Turbo-charged |

| Gear | 4 forward 4 back |

| Oil Tank | 16L |

| Water Tank | 620L |

| Water Supply | Time relay |

| Overall Dimensions | 7800*2720*3300 mm |

| Drum Rotate | 270° |

LUTON LT3.5, as the star model of self loading concrete mixer products, is exquisitely designed in detail and configured with top-leveled components. With compact body structure, flexible and efficient performance, the practical machine has been widely used in many countries and areas all over the world. More and more praise and good application feedback information return to LUTON, which is the best confirmation for LUTON product quality and sales service.

Why Choose LT3.5 Diesel Self Loading Mixer Truck To Eswatini

Taking into account the actual project requirements of the customer and the specific conditions of the project location, the sales consultant team of LUTON provided the customer with a procurement plan for LT3.5. A total of three self loading mixer trucks were purchased in this batch. Why LT3.5?

High Integration Of Multiple Functions

Firstly, this is due to the powerful functional advantages of LT3.5 self loading concrete mixer truck. It integrates various equipment functions such as loaders, mixers, and transport vehicles into one set, and can achieve the entire process of concrete preparation and transportation, equivalent to a small-scale portable concrete mixing plant. It provides efficient and convenient raw materials supply for concrete constructions.

No Additional Equipment Required

In community construction, decentralized road projects or stadium construction sites, customers do not need to separately purchase and schedule:

- Front-end loader (used for loading sand and gravel)

- Concrete mixing plant (or large mixer)

- Concrete mixing and transportation vehicle (tanker)

- Water supply vehicle (with its own water tank)

Streamlined Process

A single piece of equipment can complete the entire process of “ material collection – mixing – transportation – on-site unloading “, significantly simplifying the construction process and management complexity.

Perfect Adaptation To Swaziland’s Infrastructure Conditions

- Power Supply Restrictions

Power supply may be unstable or insufficient in some parts of Swaziland, especially in rural or emerging development areas. Traditional fixed mixing plants rely on stable electricity, while LT3.5 is diesel-powered and is completely unrestricted by the power grid, and can work anywhere there is fuel.

- Road Condition Challenges

Community construction projects may be located in residential areas with poor road conditions, and new road construction sites are even more rugged.

Stadium projects may also involve complex terrain. LT3.5 usually has good off-road performance (four-wheel drive options are common), which can adapt to these complex, unpaved or temporary construction site roads, and deliver concrete directly to the vicinity of the pouring point, reducing secondary transportation.

- Water Source Access Issues

Water sources may not be convenient at remote construction sites. LT3.5 usually comes with a large-capacity water tank, which can be filled at at a time in a place with a water source to meet the mixing needs for a period of time, reducing the reliance on continuous water supply on the construction site.

Excellent Mobility And Flexibility

- Easy Project Switching

Customers work on multiple projects of different types and locations at the same time. As a complete mobile mixing unit, LT3.5 can be quickly transferred between different projects and put into production very conveniently, without the need to build a mixing plant at each construction site.

- Adapt To Small-scale, Decentralized Operations

Community construction and some road projects are often segmented and small-scale construction. The small and medium capacity (3.5m³per batch) of LT3.5 is very suitable for this demand, avoiding the waste of large mixing plants or tank trucks in small batch pouring ( concrete has an initial setting time and cannot be stored for a long time).

- Direct Access To The Pouring Point

It can move flexibly in narrow or restricted spaces, and unload fresh concrete directly to the final pouring location such as foundation pits, road surfaces or stadium stands, reducing the intermediate links and the risk of concrete segregation.

Remarkable Cost-effectiveness

- Low Equipment Investment Cost

The cost of purchasing one LT3.5 is much lower than the total investment required for separately purchasing a loader, a mixing plant, a tanker and a water supply vehicle.

- Reduction In Operating Costs

Labor Cost

Only 1-2 operators are needed to complete the entire process, significantly reducing labor expense. (The labor costs in Swaziland may be relatively low, but the cost of managing and coordinating multiple machines still exists.)

Fuel Cost

Although the fuel consumption of a single piece of equipment may not be low, compared to the total fuel consumption when multiple pieces of equipment operate simultaneously, and considering that it avoids the empty driving mileage of the tanker truck between the mixing plant and the construction site, the overall fuel efficiency may be better.

Maintenance Cost

Maintaining a single piece of equipment is simpler and less costly than maintaining a fleet consisting of multiple devices.

Reduce Waste

Performing on-demand mixing, conducting on-site mixing at the construction site this basically eliminates the waste of concrete during transportation and the risk of scrapping caused by waiting and scheduling issues.

Convenience Of Operation And Maintenance

The operation is simple. Compared to managing and coordinating multiple devices and teams, operating a single integrated device places relatively fewer requirements on the operator, making training much easier.

Maintenance is convenient. As a brand specializing in such equipment, LUTON structural design usually takes into account practicality and ease of maintenance. In the case of limited technical resources in Swaziland, the relatively simple mechanical structure is easier to maintain and repair compared to the complex fixed-type mixing station.

Accessory supply is wide broad. LUTON usually has a certain sales and service network in the African market (through agents). Compared to some high-end niche brands, the availability of its common accessories may be better.

Meet The Specific Needs Of The Project

Community construction: Usually carried out in residential areas, with limited space, narrow roads, and the need to reduce noise and interference. The miniaturization, mobility and on-site mixing characteristics of LT3.5 are very suitable.

Stadium construction: Involving structures such as stands and platforms, concrete needs to be transported to different heights and positions. LT3.5 can be close to the operation point and unload through its own hydraulic system or external chute.

Road construction: Especially rural roads or segmented construction, there are many points and long lines. LT3.5 can be pushed along the construction route like a “mobile mixing station”, mixing and using, with high efficiency.

Brand Reliability And Market Reputation

LUTON is a well-known brand in the field of self-loading and unloading mixer trucks, especially in developing countries. Its products are known for their durability and high cost performance. Customers choose LT3.5, probably based on their recognition of LUTON brand reliability, or refer to other successful cases (in other African countries or in Swaziland).

Self Loading Concrete Mixer for Sale

LT1.2 Self Loading Concrete Mixer Truck

LT6.5 Self Loading Concrete Mixer

LT4.0 Self Loading Concrete Mixer

LT2.6 Self Loading Concrete Mixer

LT2.0 Self Loading Concrete Mixer

5.5m3 Self Loading Concrete Mixer

3.5m3 Self Loading Concrete Mixer